Introduction: Why Active and Smart Packaging in Vegetables?

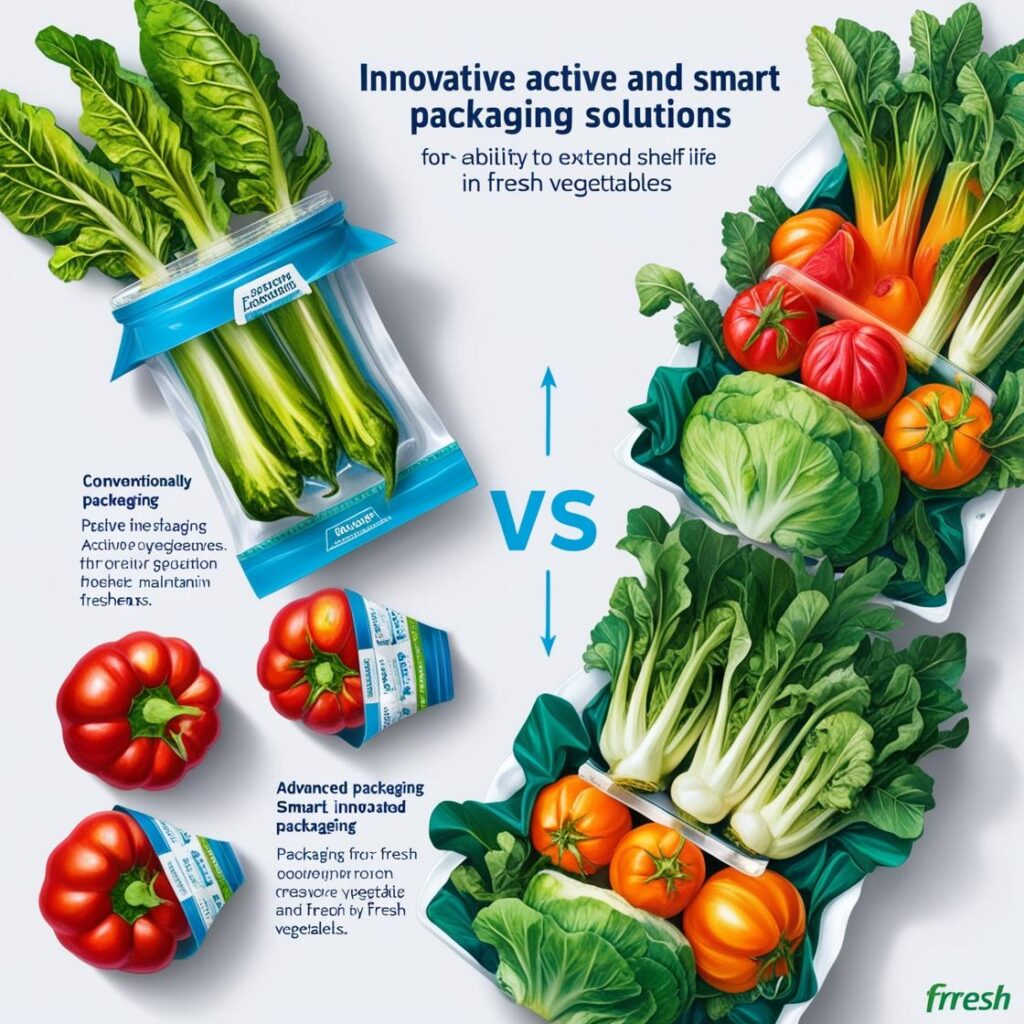

The demand for fresh vegetables has skyrocketed due to the benefits they offer—high levels of antioxidants, vitamins, and other essential nutrients. As busy lifestyles push for convenience, fresh, ready-to-use vegetables become more popular. Yet, keeping these products fresh is challenging. Fresh produce, unlike processed foods, continues to respire after harvest, leading to rapid spoilage. With the help of active and smart packaging, we can extend freshness, maintain quality, and reduce food waste.

Active Packaging Systems: Extending Freshness Actively

Active packaging is not just a container but works to keep produce fresh. By integrating certain additives directly into the packaging, it can regulate gases, absorb unwanted substances, and even release preservatives when needed.

1. Ethylene Control

Ethylene is a natural plant hormone that speeds up ripening. By absorbing ethylene, active packaging prevents premature ripening, maintaining the freshness and firmness of vegetables like tomatoes, cucumbers, and carrots. Common ethylene-absorbing materials include potassium permanganate and minerals like zeolite and activated carbon.

Actionable Tip: If you’re handling vegetables that release ethylene gas, such as tomatoes or peppers, try storing them in ethylene-absorbing bags or with ethylene absorber sachets.

2. Oxygen Scavengers

Oxygen can encourage spoilage and degrade the quality of fresh produce. Oxygen scavengers, often made from iron powder or ascorbic acid, remove oxygen from packaging, preserving freshness and color. These scavengers work by either self-reaction or reacting with moisture inside the package.

Actionable Tip: Look for packaging with oxygen-absorbing sachets or films, especially for vegetables prone to browning or discoloration like lettuce and mushrooms.

3. Carbon Dioxide Generators

High levels of carbon dioxide can slow down the respiration rate of vegetables, delaying spoilage. Packaging that generates carbon dioxide creates an environment that discourages microbial growth while avoiding the anaerobic conditions that can lead to undesirable odors or textures.

Actionable Tip: Select packaging that allows for a balanced gas exchange, such as modified atmosphere packaging, if you want your produce to stay fresh longer in the fridge.

4. Temperature-Compensating Films

Temperature shifts, especially during transport, can damage fresh produce. When temperatures rise, respiration rates increase, leading to faster spoilage. Temperature-compensating films adjust their permeability based on temperature, allowing more oxygen when it’s warmer and less when it’s cooler.

Actionable Tip: When purchasing packaged fresh produce, look for “temperature-sensitive” or “breathable” packaging. This can prevent premature spoilage, especially in warmer climates.

Smart Packaging: Real-Time Monitoring for Freshness

Smart packaging is a step beyond active packaging. It includes sensors and indicators that monitor freshness, quality, and temperature changes in real time.

1. Freshness Indicators

Freshness indicators change color based on the quality of the produce, allowing consumers to see when their vegetables are nearing spoilage. These indicators are often based on pH changes that occur as vegetables degrade.

Actionable Tip: Keep an eye on packaging with freshness indicators, which can help you avoid eating produce that’s past its peak.

2. Temperature Indicators

For perishable goods like vegetables, temperature is crucial. Temperature indicators track exposure to high temperatures and alert consumers to potential spoilage risks.

Actionable Tip: For groceries that need to be transported in warm climates, look for packaging with temperature indicators to ensure produce hasn’t been compromised during transit.

3. Time-Temperature Integrators

These smart tools measure both time and temperature, which together affect produce quality. By integrating both elements, they give a more precise indication of shelf life.

Actionable Tip: For online orders or grocery delivery, check for time-temperature integrators that let you verify freshness, particularly if the produce traveled long distances.

Nanotechnology in Smart and Active Packaging

Nanotechnology enhances both active and smart packaging by making materials more efficient at gas regulation, microbial control, and quality monitoring. For instance, nano-coatings on packaging films improve their barrier properties and make them more sensitive to environmental changes.

Actionable Tip: For extended storage, try finding products with nanotech-based packaging, as it can better handle fluctuations in storage conditions, helping your produce last longer.

Future Prospects

Active and smart packaging are evolving rapidly, with innovations aimed at making these systems more affordable, eco-friendly, and precise. Future packaging will likely focus on fully biodegradable materials, integrated tracking through IoT, and smarter sensors that monitor multiple aspects of food quality.

Key Takeaways for Social Media or Infographics

- Ethylene Control: Reduces ripening, extending freshness of ethylene-producing vegetables like tomatoes and cucumbers.

- Oxygen Scavengers: Prevent spoilage by removing oxygen, ideal for browning-prone produce.

- Carbon Dioxide Generators: Slows down respiration, extending shelf life for high-moisture vegetables.

- Temperature-Compensating Films: Adjusts to temperature changes, preventing premature spoilage.

- Freshness Indicators: Color changes show when vegetables are nearing spoilage.

- Temperature Indicators: Alerts consumers to potential spoilage due to temperature exposure.

- Nanotechnology: Improves gas regulation, microbial control, and adaptability to storage conditions.

This approach to packaging brings us closer to a world where our food waste is minimized, our produce is fresher for longer, and consumers have peace of mind knowing the food they eat is safe and nutritious.

Title: Active and Smart Packaging for Vegetables: The Future of Freshness

Introduction

With consumer demand for fresh produce on the rise, the need for effective packaging solutions has never been more critical. Many of us know the disappointment of buying fresh vegetables, only to have them spoil within days. This article will guide you through the fascinating world of active and smart packaging technologies designed to keep your vegetables fresh for longer, from ethylene control to microbial resistance.

Imagine you’re at your local store, looking at two packs of lettuce—one boasts an extended freshness claim, while the other has no added features. The former likely uses active or smart packaging technologies, carefully developed to extend shelf life and quality. These packaging methods are not just about storing food; they actively interact with produce, enhancing its longevity and keeping it safe from spoilage. Let’s break down these innovative techniques to see how they help prevent food waste and offer longer-lasting, fresher produce.

1. Active Packaging Systems

Active packaging takes a proactive approach to maintaining freshness by interacting with the produce inside. Here are some key techniques:

Ethylene Control

- Purpose: Ethylene is a plant hormone that accelerates ripening. By controlling it, packaging can delay senescence (aging) in vegetables.

- How It Works: Ethylene scavengers like potassium permanganate and zeolite absorb ethylene inside the packaging. These are often incorporated as sachets.

- Common Applications: Tomatoes, cucumbers, and carrots benefit from ethylene control systems to extend freshness.

Actionable Tip: Look for produce labeled as having “ethylene control” or “extended freshness technology” to enjoy a longer-lasting product.

Oxygen Scavengers

- Purpose: Oxygen encourages spoilage; removing it can significantly extend shelf life.

- How It Works: These scavengers contain iron powder or ascorbic acid, which react with oxygen to eliminate it.

- Common Applications: Suitable for low-moisture vegetables where oxygen exposure would normally cause spoilage.

Actionable Tip: For home storage, you can use vacuum-sealed containers to minimize oxygen, similar to these packaging principles.

Carbon Dioxide Generators

- Purpose: Carbon dioxide slows the growth of aerobic bacteria.

- How It Works: CO₂ is released inside packaging through a chemical reaction, often using sodium bicarbonate and acid.

- Best for: Moist, fresh vegetables like spinach and cut fruit, where bacterial growth needs to be managed.

Actionable Tip: When choosing fresh-cut produce, look for packaging that mentions “CO₂ protection” to benefit from added freshness.

Humidity and Condensation Control

- Purpose: Excess moisture leads to bacterial and fungal growth.

- How It Works: Drip-absorbent sheets with super-absorbent polymers capture extra water, while humectants like propylene glycol balance humidity.

- Key Benefit: Reduces mold growth in high-humidity produce like lettuce and berries.

Actionable Tip: For moisture-prone vegetables, select packs that mention “humidity control” or have visible absorbent pads.

Odour Control

- Purpose: Prevents unwanted odors from vegetables such as onions and garlic.

- How It Works: Odor-absorbing materials, such as activated charcoal, trap odors and prevent cross-contamination.

- Ideal for: Pungent vegetables like onions and leeks.

Microbial Control

- Purpose: Inhibits bacteria, mold, and yeast growth to keep vegetables safer.

- How It Works: Antimicrobial agents like ethanol, carbon dioxide, and natural preservatives are incorporated into packaging.

- Uses: Works well for fresh-cut vegetables, where spoilage microorganisms are a risk.

Actionable Tip: Consider packaging that lists antimicrobial properties for sensitive produce such as leafy greens.

2. Smart or Intelligent Packaging

Intelligent packaging goes beyond simply extending shelf life—it gives consumers and retailers real-time information about the product’s freshness.

Freshness Indicators

- Purpose: Visual indicators that inform you of the product’s quality.

- How It Works: Sensors change color based on the presence of certain gases, such as ammonia, that indicate spoilage.

- Common Applications: Fresh-cut fruits and vegetables, especially in grocery stores.

Actionable Tip: Keep an eye out for freshness indicators to make informed choices about produce quality.

Time-Temperature Indicators (TTI)

- Purpose: Tracks temperature changes that could affect the freshness of the vegetables.

- How It Works: Labels or stickers that visually display if the produce has been stored in inappropriate temperatures.

- Best for: Temperature-sensitive produce like leafy greens and tomatoes.

Actionable Tip: For the freshest produce, opt for items with TTI labels, especially if you’re buying in bulk or planning to store the vegetables.

Summary of Key Takeaways for Freshness

To wrap up, here are the essential points to remember when choosing fresh produce packaging. These can also serve as quick visual takeaways for social media or infographics:

- Ethylene Control: Look for ethylene-scavenging packaging for produce that ripens quickly.

- Oxygen and CO₂ Generators: Choose produce that benefits from oxygen control and CO₂ generators for longer freshness.

- Humidity Control: Opt for moisture-controlled packaging for sensitive items like lettuce.

- Odour Control: Odor-absorbing packaging keeps strong smells from overpowering other foods.

- Microbial Control: Antimicrobial packaging can help protect against bacteria and mold.

- Smart Indicators: Freshness indicators and TTIs on packaging help monitor the quality of produce in real time.

By understanding and utilizing these advanced packaging technologies, consumers can enjoy fresher, safer produce and reduce waste.

This text covers a range of advanced packaging technologies for monitoring and maintaining the quality and freshness of packaged foods, specifically vegetables and fruits. Here’s a summary of each key section:

1. Gas Indicators

- Purpose: Detect changes in gas composition within packaging to monitor freshness, maturity, and integrity.

- Types: Primarily oxygen and carbon dioxide indicators. These change color due to chemical reactions, helping identify package leaks, oxygen absorption, and quality issues.

- Examples: Ageless Eye by Mitsubishi Gas Chemical changes color to indicate low oxygen levels.

2. Time and Temperature Indicators (TTIs)

- Purpose: Track the exposure of products to temperature over time, crucial for maintaining quality during distribution.

- Types: Biological, chemical, or physical reactions (e.g., color changes) are used to show if the product has been kept within safe temperatures.

- Examples: Fresh-Check and Vitsab TTIs change color based on temperature exposure, useful for cold-chain items like fresh produce.

3. Microbiological Spoilage Indicators and Pathogen Sensors

- Purpose: Detect microbial spoilage or specific pathogens within packaging.

- Method: Measures volatile compounds produced by spoilage (e.g., CO₂, ammonia). Advanced sensors can detect bacteria using embedded antibodies or nanoparticles.

- Advances: Nanosensors with long-term stability and biocompatibility offer potential for reliable spoilage and pathogen detection.

4. Freshness Indicators

- Purpose: Monitor freshness based on volatile metabolites emitted by the produce.

- Application: Detect gases like ethanol and carbon dioxide, with color-based indicators that show the level of freshness.

- Example: RipeSense® for fruit ripeness, using aroma compounds to signal maturity.

5. Radio Frequency Identification (RFID)

- Purpose: Use radio waves for tracking product history and conditions during distribution.

- Example: X-TrackTM integrates RFID and TTIs to continuously monitor and store data, accessible remotely, for temperature and handling insights in the supply chain.

6. Nanotechnology in Packaging

- Purpose: Enhances food packaging by improving barrier properties, providing antimicrobial effects, and supporting freshness.

- Benefits: Extends shelf life, improves safety, and may even respond to spoilage by releasing preservatives.

- Examples: Durethan, a nanocomposite film by Bayer, reduces oxygen entry and moisture loss to keep food fresh longer.

7. Future Prospects

Future developments may include edible coatings with embedded smart packaging technologies

Intelligent packaging is evolving toward interactive designs that respond dynamically to produce needs, using flexible electronic components and biosensors.

About Us

Welcome to Agriculture Novel, your go-to source for in-depth information and insights into the world of agriculture, hydroponics, and sustainable farming. Our mission is to educate, inspire, and empower a new generation of farmers, hobbyists, and eco-conscious enthusiasts. Whether you’re interested in traditional farming practices or modern innovations, we aim to provide comprehensive guides, expert tips, and the latest updates in agriculture and urban farming.

At Agriculture Novel, we believe in the power of knowledge to transform the way we grow, sustain, and nourish our world. Explore our articles on topics like Fruit Growing Guide, Hydroponics, Plant Deficiency Guide, and more.

Thank you for joining us on this journey towards a greener, more sustainable future!

About Agronique Horizon

At Agronique Horizon, we specialize in delivering comprehensive digital marketing and web development solutions tailored for the agriculture and hydroponics industries. From custom website design and app development to social media management, we provide end-to-end support for brands aiming to make a meaningful impact. Our team also offers innovative solutions for the real estate sector, bringing precision and visibility to your projects. Learn more about our services here and discover how we can elevate your digital presence.